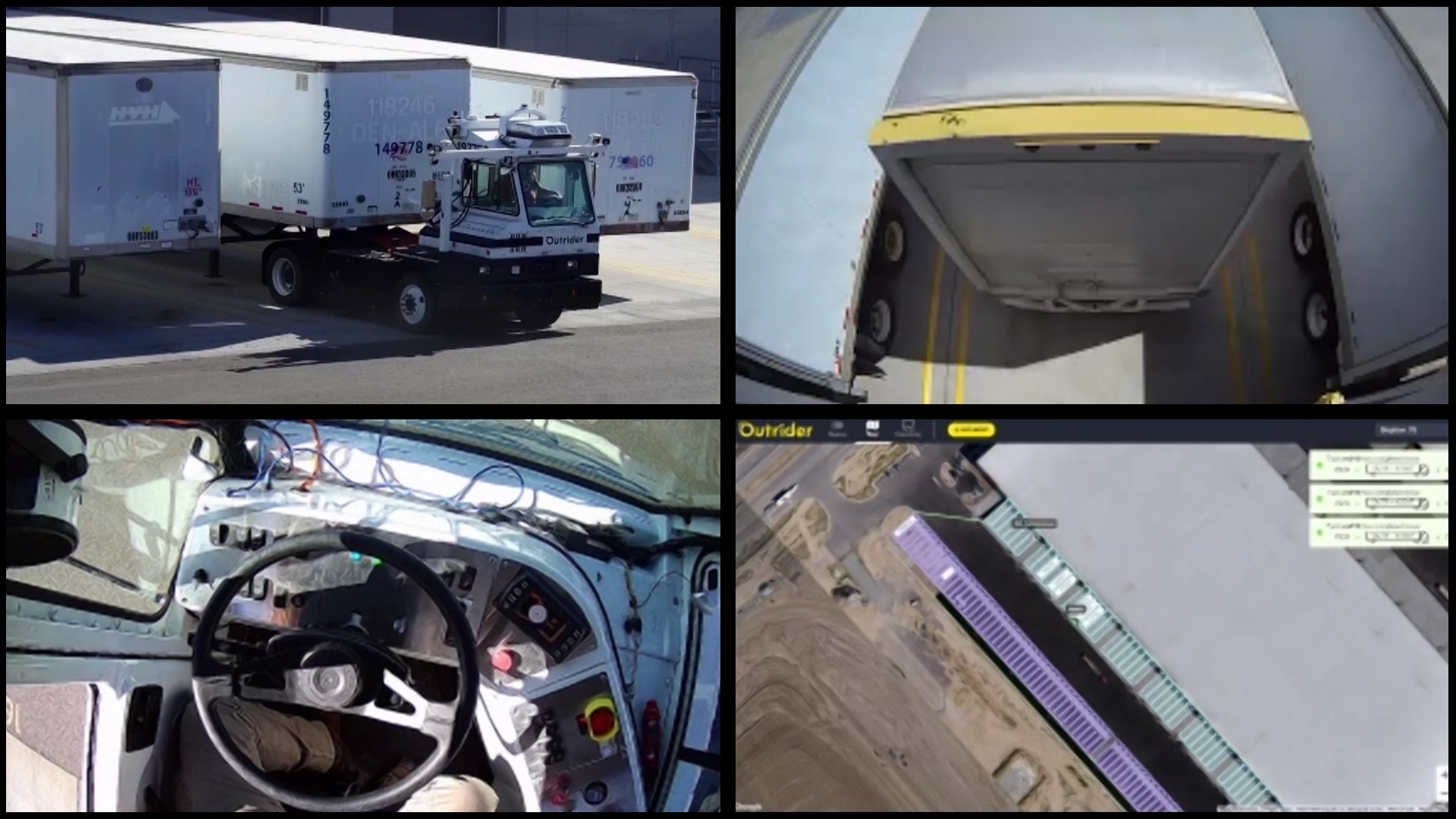

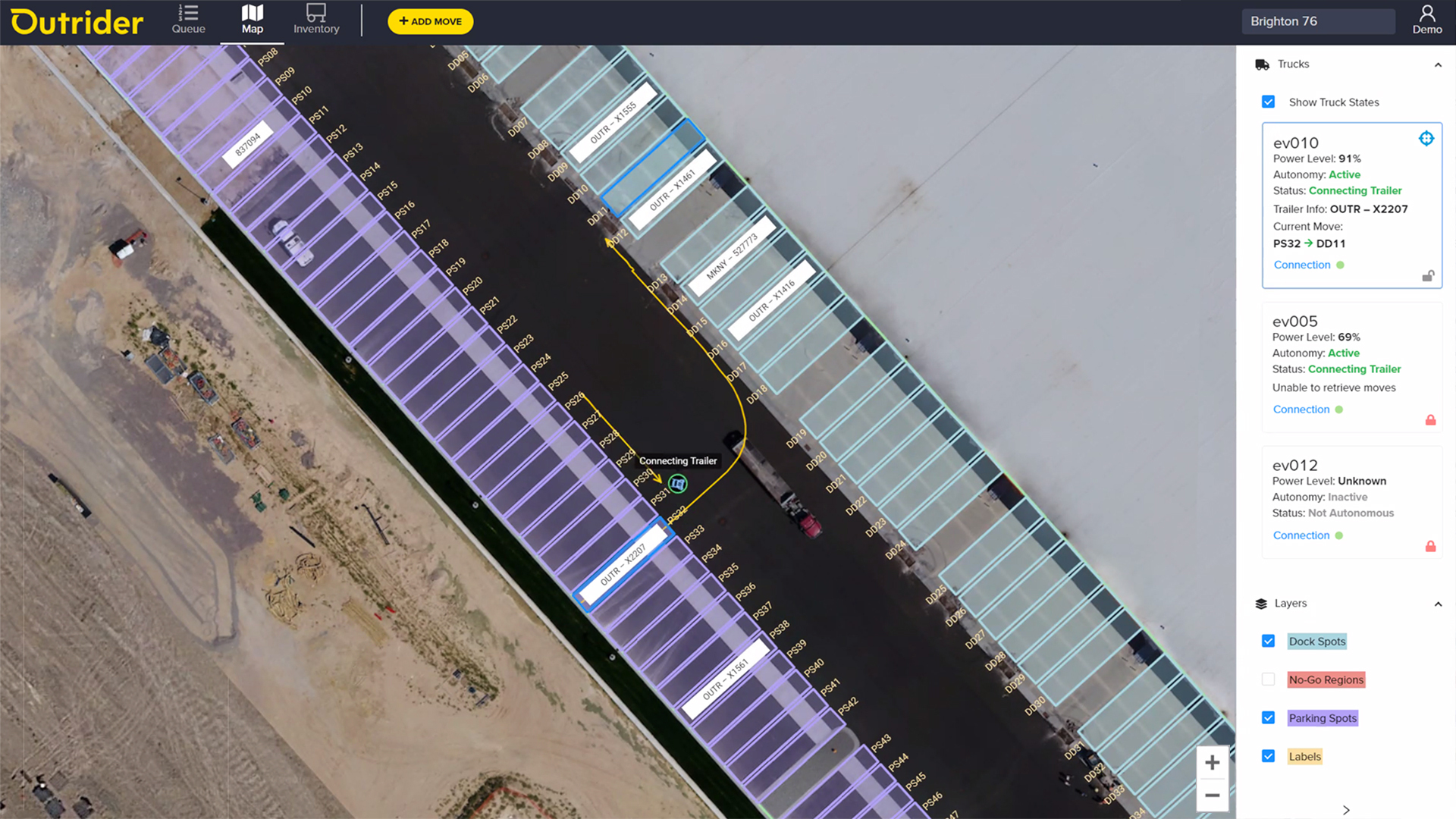

| By Ira Boudway Yard trucks: also known as spotters, shifters, shunt trucks, and terminal tractors, or, for those who prefer zoological nomenclature, yard birds, horses, dogs, or mules. By any name, they are the vehicles that tow semi-trailers from dock to dock and parking spot to spot at warehouses and shipping yards. Last week, I tried my hand operating one. I'm proud to report that, on my first try, I successfully backed a 53-foot trailer into a dock sandwiched by two other trailers. Well, more precisely, I sat at a laptop at my dining room table in suburban New Jersey, clicked a few simple commands and then watched online as a yard truck at a warehouse in Brighton, Colorado, drove to a parked trailer, hitched to it, towed it about 150 feet to an empty dock, backed in, and unhitched — all without human intervention. My debut as a warehouse dispatcher was arranged by Outrider Technologies Inc., a Colorado startup that makes self-driving yard trucks. Outrider is another example of automated and electric vehicles finding uses in agricultural and industrial spaces, where they can do dirty and dangerous jobs without encountering passengers or pedestrians.  Photographer: Outrider Photographer: Outrider "We identified that autonomous vehicles in a private property, low speed application like a distribution center could have a huge impact," says Outrider CEO Andrew Smith, who founded the company in 2017 and ran it in stealth under the name Azevtec until last year. There are, Smith estimates, about 50,000 yard trucks in operation in the U.S. at any given moment. Collectively, they make millions of trips every day, usually belching out carbon dioxide as they go. Annual yard truck sales in the U.S. are about 3,500 and growing, according to Tim Denoyer a senior analyst at ACT Research. Most run on diesel, but, according to Denoyer's estimates, 10% to 15% of sales this year will be electric. "The yard spotter is one of the first movers to electrify," he says, "mostly because of the lack of range anxiety and because the fuel efficiency of diesel spotters is awful." Driving a yard truck is a repetitive job that takes time to master and usually doesn't pay as well as long-haul work. Turnover is high. In addition to towing trailers in busy lots and backing them into tight spaces, drivers need to get down from the cab for every hitch to connect a pressurized air hose to the trailer to release its parking brake — a task that Outrider has had to figure out how to automate.  Source: Outrider Technologies Inc. Source: Outrider Technologies Inc. The startup buys electric yard trucks from manufacturers such as Orange EV and outfits them with cameras, radar, and lidar sensors to guide its self-driving software. Earlier this year, the company opened a 350,000 square-foot warehouse and yard in Brighton, north of Denver, to build and test its vehicles. For most of the day, a handful of AVs tow trailers to and from the site's 49 dock doors. Outrider has nine pilot customers testing its system, which includes the trucks, dispatch management software, and a help center at its headquarters in Golden. For now, safety drivers sit behind the wheel of every truck with a big red button that allows them to shut off the robot and take over. Outrider hopes to go fully driverless sometime in 2023. Last week, when I was the first reporter allowed to test the system, the safety driver didn't need his button. After a brief tutorial from Outrider's vice president of product, Peter James, I was able to use the pulldown menu on the online dashboard to instruct a tractor to pick up the trailer from parking spot 38 and drop it at dock 15. A robotic arm at the back of the truck handled the job of hooking and unhooking the air hose. Altogether, it took about ten minutes, slower than the average human driver could do it, but without flaw. Speed will come later, James says. For now, the focus is on "precision and repeatability of moves" and making the job so easy that a newbie like me can do it. If you're a Bloomberg Green subscriber and want to start getting the Hyperdrive newsletter, sign up here. If you're a Hyperdrive subscriber and want to start getting our daily Green newsletter, sign up here.

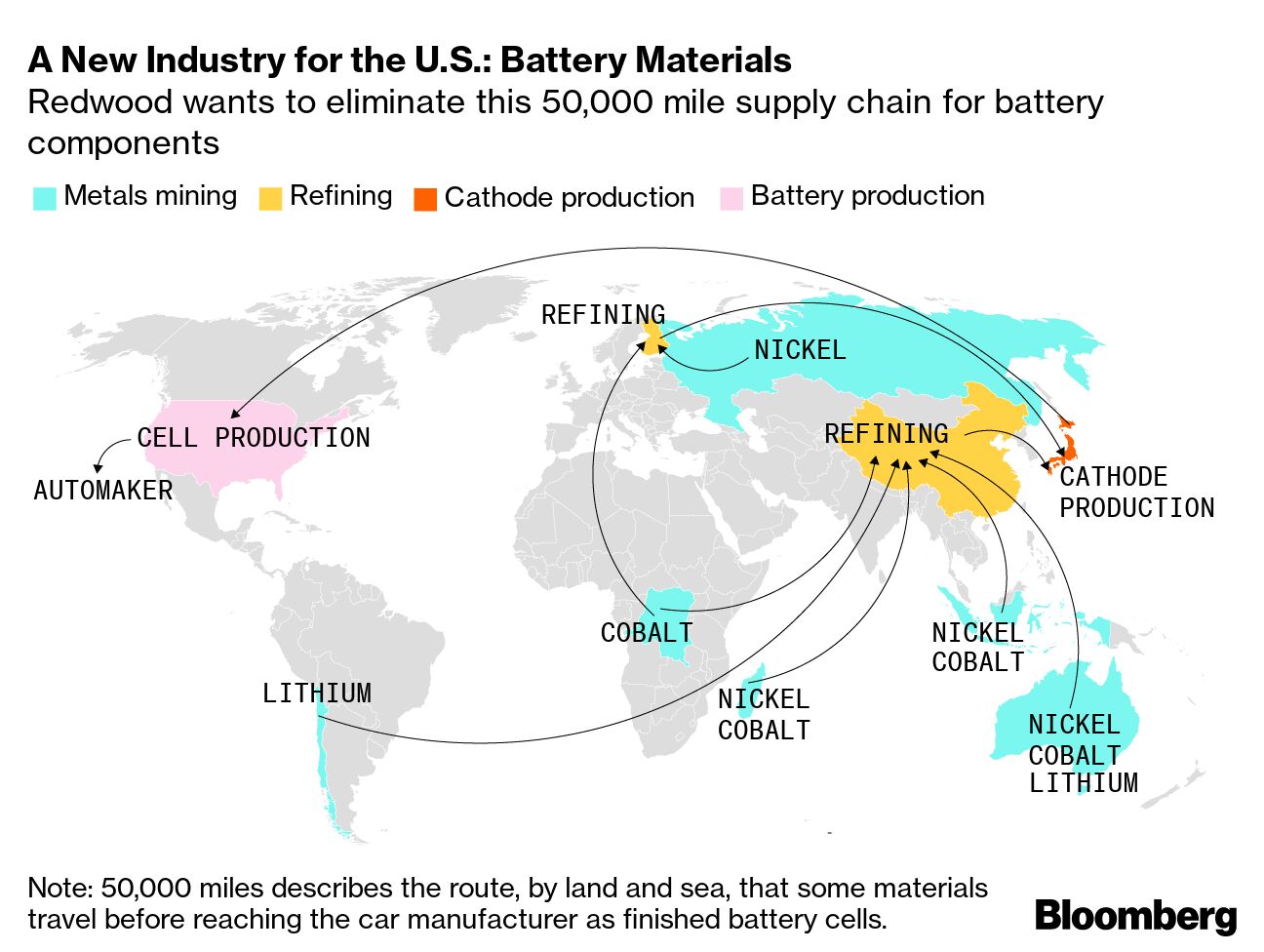

Like getting the Green Daily newsletter? Subscribe to Bloomberg.com for unlimited access to breaking news on climate and energy, data-driven reporting and graphics, Bloomberg Green magazine and more. You can read today's newsletter on our website here. Redwood Materials, the battery recycling company created by Tesla co-founder J.B. Straubel, has been keeping a big secret: It isn't really a recycling company. Sure, Redwood is the biggest lithium-ion battery recycler in the U.S., but Straubel didn't leave Tesla in 2019 just to clean out America's junk drawers. His broader goal is to move a huge chunk of the battery-component industry from Asia to the U.S.  |

Post a Comment